+91 981-032-2070 info@xtrememachines.in

About us

COMPANY PROFILE

Basic Information

Nature of Bussiness

Exporter and Manufacturer

Additional Business

Supplier

Proprietor

Kulwant Singh(Monty Singh)

Registered Address

Plot No. 72/6, Khasra No. 72/9/2/1, Metro Pillar #485, Swarn Park, Mundka, Rohtak Road, New Delhi 110 041 (INDIA)

Total Number of Employees

30 to 34 Employees

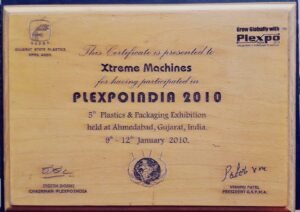

Year Of Establishment

1982 (Kneader house)

Present (Xtreme Machines)

Legal Status of Firm

Individual – Proprietor

Annual Turnover

10-12 Crore

Trade & Market

Export Percentage

25%

Infrastructure

Location Type

Urban

Size of Premises

1600 Sq. Yard

Company USP

Primary Competative Advantage

- Experienced R & D Department

- Good Financial Position & TQM

- Large Product Line

- Large Production Capacity

- Provide Customized Solutions

Contract Manufacturing

Buyer Label Offered

Statutory Profile

Import and Export Code(IEC)

05120***

Banker

- PUNJAB NATIONAL BANK

- KOTAK MAHINDRA BANK

GST No.

07AVCPS8642K1Z1

Packaging/Payment and Shipping Details

Customizing Packaging

Yes

Payment Mode

- Cheque

- DD

- Online

- Bank Transfer

- RTGS

- Cash

- Credit Card

Shipment Mode

- By Air

- By Road

- By sea

- By Cargo

Company Album

Production House

Our Infrastructure

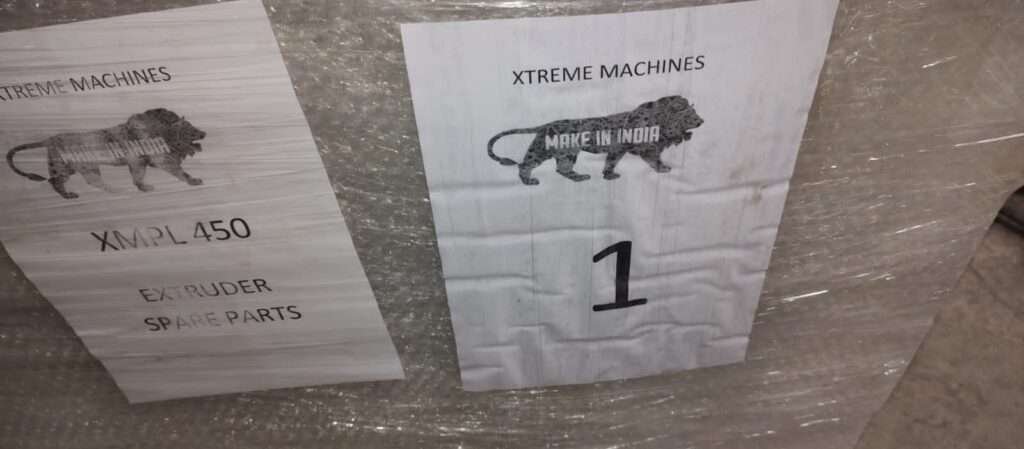

Our Warehouse

Our Infrastructure

At Xtreme Machines, we pride ourselves on being at the forefront of innovation and technology in the production of engineering machines. Our commitment to excellence is reflected in our state-of-the-art machinery and sophisticated technology, which enable us to manufacture premium quality Rubber and Plastic Processing Machines. As a leading manufacturer, exporter, and supplier in the industry, we have established a strong clientele worldwide.

- Services after Sales

- Commitment to Excellence:

- Global Industry Leader

- Comprehensive Product Range

- Customer Satisfaction:

- Innovation and Continuous Improvement:

- Dedication to Quality

Quality Compliance

Stringent Quality Control Processes: Xtreme Machines implements rigorous quality control processes at every stage of production. From raw material inspection to final product testing, each step is meticulously monitored to ensure that only products meeting the highest quality standards are released to the market.

Continuous Improvement Culture: The company fosters a culture of continuous improvement, where employees are encouraged to identify areas for enhancement and implement corrective actions. By constantly refining its processes and procedures, Xtreme Machines strives for excellence and stays ahead of industry quality benchmarks.

Customer Feedback Integration: Xtreme Machines places a strong emphasis on customer feedback and satisfaction. Feedback from customers is systematically collected and analyzed to identify areas for improvement. By incorporating customer insights into its quality management processes, the company ensures that its products consistently meet or exceed customer expectations.

Supplier Quality Assurance: Xtreme Machines works closely with its suppliers to ensure the quality of raw materials and components used in its manufacturing processes. Supplier performance is closely monitored, and only trusted suppliers who consistently meet quality standards are retained, contributing to the overall quality compliance of the final products.

Regulatory Compliance: Xtreme Machines adheres to all relevant regulatory requirements and industry standards governing the manufacturing of engineering machines. By staying abreast of regulatory changes and proactively updating its processes accordingly, the company ensures compliance with all applicable quality and safety regulations.

Our Warehouse

Packaging & Loading of the machine